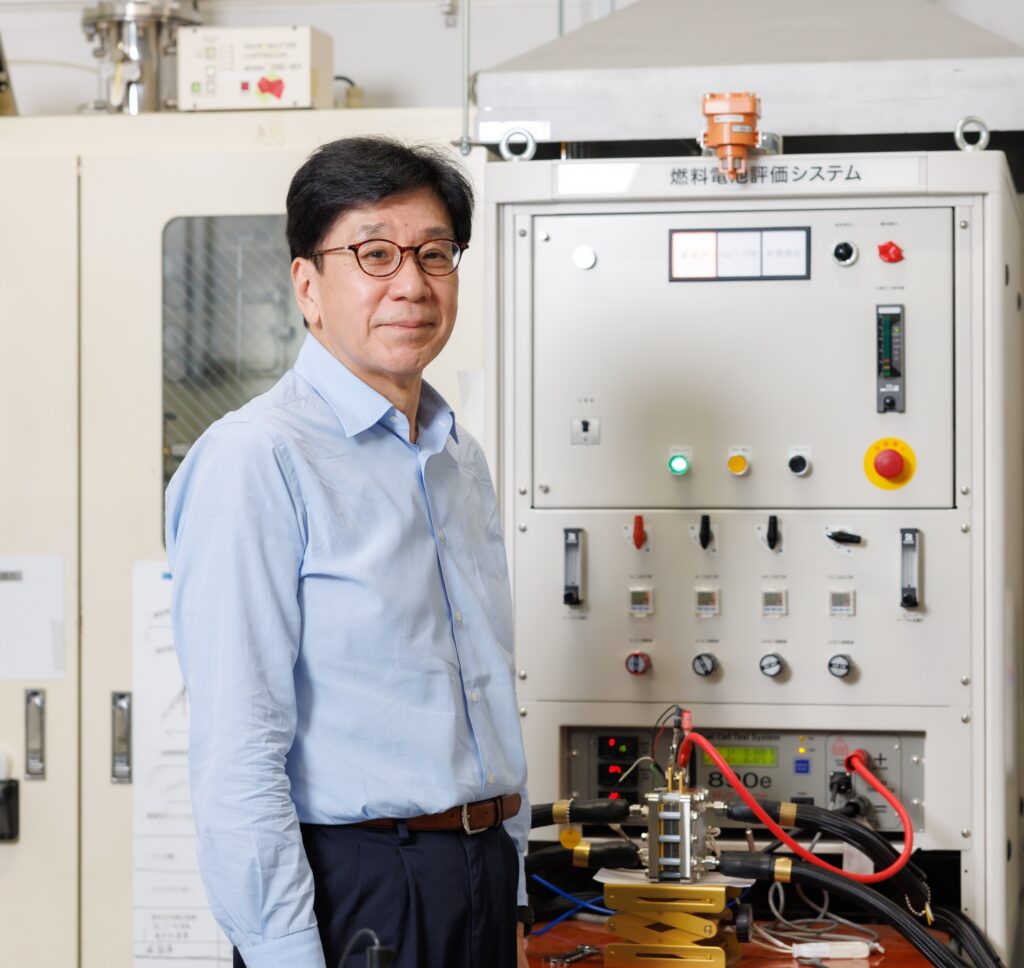

Polymer electrolyte fuel cells are installed in eco-friendly cars. Professor Masahiro Rikukawa from the Faculty of Science and Technology undertakes research in functional polymers with potential as electrolytes for these fuel cells. He talks about the appeal of research that spans the entire process from materials design to application, and the fun of manufacturing.

Molecules are formed by atoms, and joining many of them together forms a macromolecule called a polymer. By modifying the structures of polymers or combining them with other substances, we can create polymers with novel properties like superior water absorption or conducting electricity as well as metals.

My research theme is the development of functional polymers with such special properties. In particular, I focus on research about proton-conducting polymers, which have the potential to be electrolyte materials of fuel cells.

Polymer electrolyte fuel cells are installed in fuel cell vehicles, which are considered to be the pinnacle of eco-friendly cars. In fuel cell vehicles, hydrogen supplied from a hydrogen station is ionized in the electrode to generate electricity. Currently, lithium-ion batteries are the mainstream of electric car energy source, but their energy density per unit weight is low and it is difficult to install them on buses, trucks and such that carry cargo and people over long distances.

On the other hand, fuel cells use hydrogen as fuel for power generation, alleviating concern over charging time and battery capacity. If we can develop polymer electrolyte fuel cells that are highly durable and low cost, it will also be easy to introduce them in heavy duty vehicles.

Analyzing created materials to find hints for new materials

At my laboratory, to develop products that can contribute to society, I guide research by telling people to think about how the results can be of use to society. That is also why we go beyond simply making materials, to go all the way to making our own fuel cells and confirming their performance.

In materials synthesis, the final goal is not to be able to synthesize them. We must not neglect the task of making clear the material structure, composition, —and the reaction process. This is also something that should be undertaken by a university laboratory.

If we think of manufacturing as cooking, the chefs are companies, who continue to pursue tasty dishes single-mindedly for the sake of customers. The job of researchers is to support them behind the scenes by analyzing in detail the factors that led to delicious food. If we can make clear the reasons for great taste, it will become easier to create new dishes.

The most important thing is to believe it is possible and keep thinking

On average, it takes about three years from creating a material until analyzing it. Even if things go as planned, often, they do not turn out as expected, such as being significantly smaller in quantity than predicted.

However, the most important thing is to believe it is possible and always keep thinking. I keep this in mind all the time because, at times when things do not go well, we tend to think about the reasons for failure. I feel extremely refreshed when I overcome difficulties to achieve the expected results. This is also what I find interesting about research, and I believe it is a feeling shared by people who like manufacturing.

Currently, the fuel cell I am working on has entered the stage of joint development with the government and companies. I feel motivated as well as a huge sense of responsibility. It will help to reduce CO2 emissions if high-performance polymer electrolyte fuel cells are adopted widely and become installed in many heavy duty vehicles. I intend to keep pursuing research with this goal in mind.

There are several other research themes being undertaken in parallel at my laboratory, including the development of functional polymers with high biocompatibility that serves as materials for artificial organs. I hope to convey the joy of manufacturing to young people through such research. I see this as another mission that must be undertaken for the future of Japan.

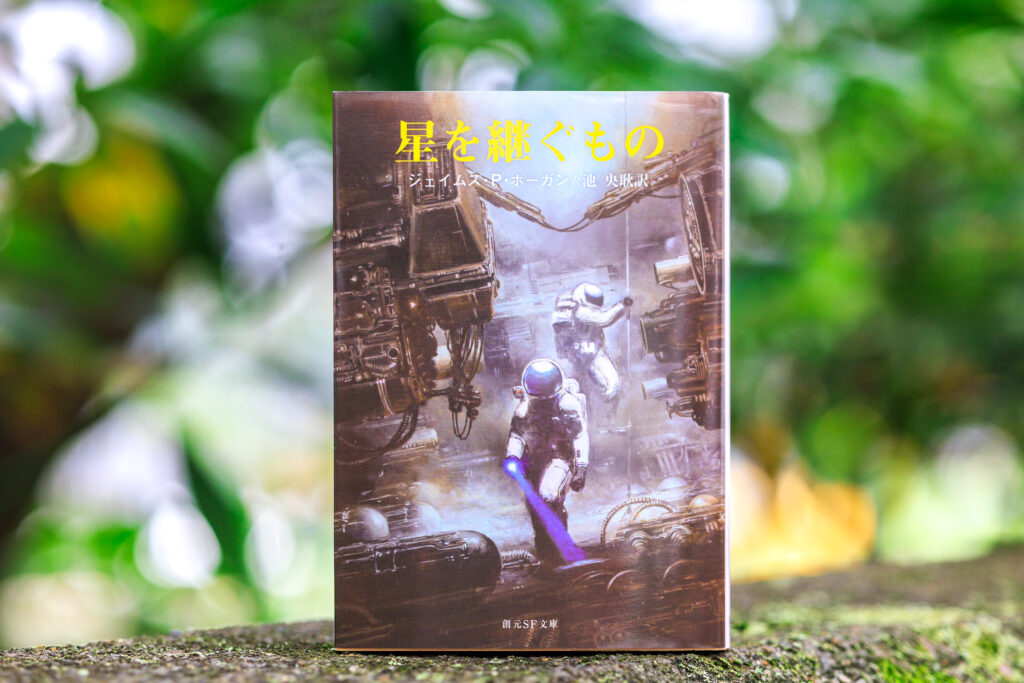

The book I recommend

“Inherit the Stars”

by James P. Hogan, Japanese translation by Hiroaki Ike, Tokyo Sogensha

I read this science fiction novel when I was a university student. Besides this book, science fiction is interesting because it can predict the world 10 or 20 years from now. The self-healing materials gaining attention now also appear in science fiction novels back then. Today, I still read this book from the perspective that there is something about science fiction that makes it formidable.

-

Masahiro Rikukawa

- Professor

Department of Materials and Life Sciences

Faculty of Science and Technology

- Professor

-

Graduated from the Department of Chemistry, Faculty of Science and Technology, Sophia University, and completed the Master’s program at the university’s Graduate School of Science and Technology. Entered Hitachi Chemical Co., Ltd. in 1985, followed by taking on several positions—such as visiting scholar at Massachusetts Institute of Technology in 1989 as well as research assistant in 1992 at the Department of Chemistry, Faculty of Science and Technology, Sophia University followed by lecturer, assistant professor, and professor—before assuming current position in 2008.

- Department of Materials and Life Sciences

Interviewed: June 2023